Minerals Production

Our standard pellet press reconditioning includes the following:

Replace Sleeves (machined with proper pocket configuration)

Recondition Shafts and Bearing Blocks

Replace Seals and Bearings

Replace Cheek Plates

Re-grease and pack for storage.

All of our components are cryogenically treated for longer wear.

We keep Cheek Plates, Pellet Sleeves and Bearings in stock, so we can quickly service all of your maintenance needs.

Complete Pelletizing Machines | Complete Component Repair and Replacement

We can also build complete machinery

or component parts for:

Block Presses

Batching Scales

Can Line Equipment

Bagging Equipment

Tube Saws (Air Motors are kept in stock)

Other Services

Large Hydraulic Press

Mig & Tig Welding

Plasma Cutter with a 5’ x 10’ table and the ability to cut up to 1” mild steel

Agriculture

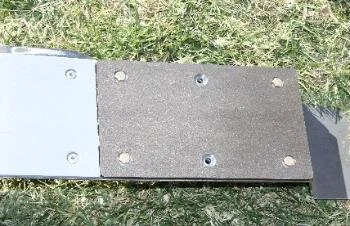

MDS has developed a skid plate set for the AGCO Draper Header. The set replaces the factory made plastic ones with an AR400 steel skid plate that helps protect the entire weldment.

We sell to individual farmers as well as dealerships and have received excellent feedback that this plate prolongs the life of the assembly and keeps machines in the field longer. Operators are able to run the headers on the ground for low-growing crops without constant worry about wear.